TEL: 038.555.2991

COMPANY

All our equipment and machines are well installed with various sizes, resins and different pieces of wood veneer. Furthermore, our workforce and QC staff are skillful and well-trained to adapt to every product specification.

Our production capacity is up to 3500 CBM/month for JAS standard LVL for furniture, structural LVL and packaging LVL

FACTORY

There are 3 factories: Factory 1 (15,000 SQM), Factory 2 (1,200 SQM),

Factory 3 (2000 SQM) is dedicated to 3 types of LVL in packaging

levels, JAS standards and structural LVL.

The factory is well equipped with ventilation, lighting, and automatic sawing systems

Vacuum cleaner, fire fighting equipment for large capacity manufacturing plants

and safe.

Each factory has its own area for storing input materials, production area, and sorting area – classifying and preserving finished products.

DEVICES

QC equipment is provided and regularly calibrated: electronic balances, thermocouples, viscometers, pH meters.

All machinery and equipment are equipped with the most modern and advanced technology to ensure accurate operating procedures, progress and product quality.

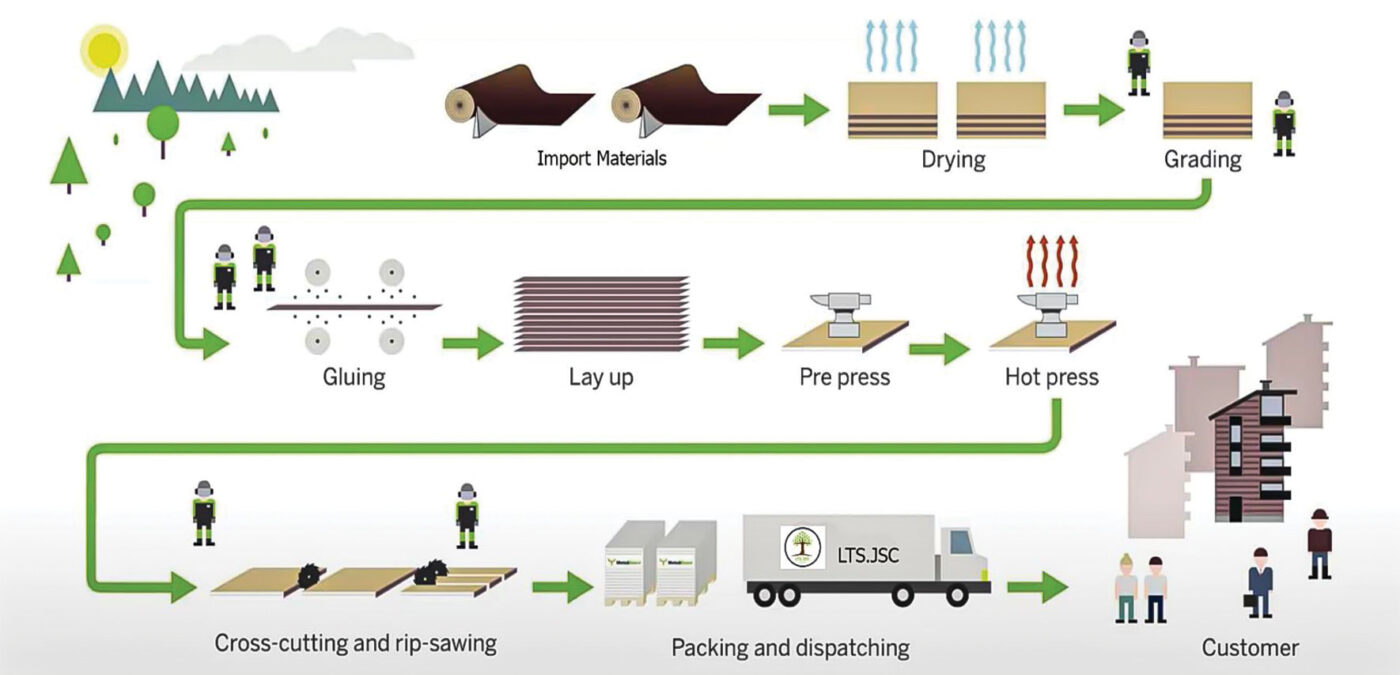

PRODUCTION PROCESS

HOW ARE OUR PRODUCTS CREATED?

To have good quality LVL, input raw materials are selectively selected for drying to have the most suitable moisture content.

The incoming boards are then pressed with the correct amount of glue and placed together on a conveyor belt before cold and hot pressing.

When the board reaches the appropriate surface roughness, the board will be sawn into finished size.

Sawn products are visually inspected for defects, dimensional tolerances and moisture content before palletizing and loading into containers.